PRODUCTS

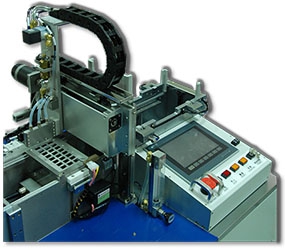

CF-8250

Automatic Ink Marking Machine

Specification Table

Introduction

Multifunction machine, including H2 burning, ink marking, visual inspection, and defective product exchange.

Characteristic

Automatic Loading and unloading module

Able to load 25 trays, also can replenish products in dynamics.

The motor control system

Adopts step control, and it can set the multi-point positioning arbitrarily with input parameters by man-machine interface.

Change the surface tension of the gel

To increase the adhesion of the print.

The entire folder of the marking positioning area

Prevents tray warping. Top suction module + precision positioning limit plate, which can control the marking accuracy effectively (± 0.1mm).

High capacity setting

Can be marking in single row or multiple rows. (package size need to less than 27x27mm)

Defective product discharge area

The product temporary storage area when the equipment or product is abnormal, and beneficial to check the product status.

Motion of Pad Printer Head and ink-catching

Adopts servo control. Marking/speed/stroke/dwell-time are controllable and automatic cleaning.

With precision positioning

It can be repeated marking multiple times to increase contrast of printing.

The PLC control system

Built-in Chinese and English operation interface. It is easy and flexible to operate.

Applied Field

► BGA、Micro SD、Mini SD 、MMC、SD、M2...

Video